[Introduction]

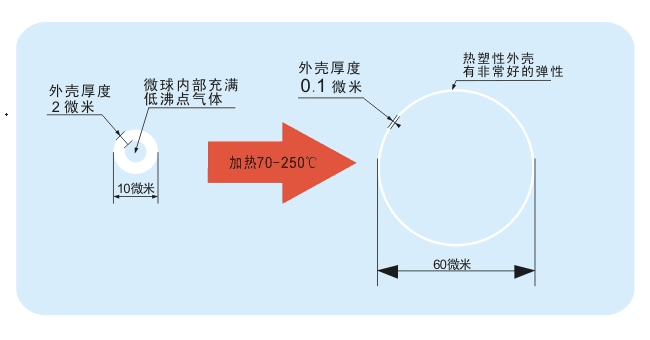

Microsphere foaming powder is a special thermoplastic plastic foaming powder. It is itself a tiny spherical hollow plastic pellet with a diameter of 8-60 microns and a true density between 1000-1300KG/M3. When heated, the thermoplastic outer shell of the outer layer of the pellet becomes soft, the volume of the microsphere changes greatly, and the fully expanded microsphere increases its volume by more than 40-60 times, reducing the density to less At 10 KG/M3. However, its core-shell structure is not destroyed, so as to achieve the effect of foaming. Its approximate foaming temperature is in the range of 70-250 °C.

【characteristic】

1. High elasticity: All microsphere foaming powders have high elasticity and the surface can withstand a pressure of 300 kg/cm 2 . The foamed microspheres are extremely easy to compress. When the external pressure disappears, they immediately return to their original shape and can withstand multiple compression and rebound processes without breaking. For example, when foaming powder is used in the manufacture of shoe materials, and it needs good impact resistance and elasticity, this is particularly prominent and important.

2. Good mechanical properties: Unlike other types of foaming agents, microsphere foaming powder has no cells, thus avoiding the disadvantages such as uneven cell pores, cell breakage, poor cell back elasticity, etc. The complete spherical structure ensures good Mechanical properties.

3. Excellent foaming performance: The microsphere foaming powder has a foaming effect of 40-60 times. The foamed microsphere is still a complete closed sphere, which has the foaming effect unmatched by the traditional chemical foaming agent.

4. Reduced density: Microsphere foaming powder can greatly reduce the density of the product, thereby reducing the amount of other main materials, making the product lighter and with better impact resistance.

5. Variety of choice: The temperature of microsphere foaming powder ranges from 70 °C to 250 °C. Customers can choose different temperature performance products according to their actual needs, different processing temperatures and process requirements.

6. Environmental performance: Microsphere foaming powder is a non-toxic and non-polluting environmentally friendly foaming agent.

[Scope of application]

1. Three-dimensional pattern: printing paste, ink printing, drawing, Braille, fabric, etc.

2. Matte and suede effect: non-woven or woven fabric, paint, paper, wallpaper, artificial leather, etc.

3. Non-slip products: carpet, cardboard, man-made fiber products, etc.

4. Buffer protection coating: leather coated bottom, automotive chassis coating, automotive interior, weaving, etc.

5. Lightweight addition: shoe material, PVC plastic, putty, epoxy resin, toys, etc.

6. Used to reduce density: automotive molds, wood, ceramics, polyurethane products, engineering rubber products, etc.

7. Make performance improvers: artificial marble, high-end bathroom products, battery electrodes, polished bodies, etc.

[add and apply]

The microsphere foaming powder is very simple to use, and it can be mixed and stirred uniformly in the system to be added, and generally it is not necessary to adjust the original process.

The amount of addition is generally 3-8 % of the system depending on the desired effect.

| Types of | Primary particle size | Starting foaming temperature | Maximum temperature |

| Low temperature | 9-16μm | 70-100°C | 135-145°C |

| Medium temperature | 9-16μm | 100-110°C | 142-152°C |

| 38-44μm | 115-125°C | 165-175°C | |

| High temperature | 9-16μm | 125-135°C | 170-180°C |

| 30-40μm | 130-140°C | 195-180°C | |

| 20-30μm | 160-180°C | 230-250°C |